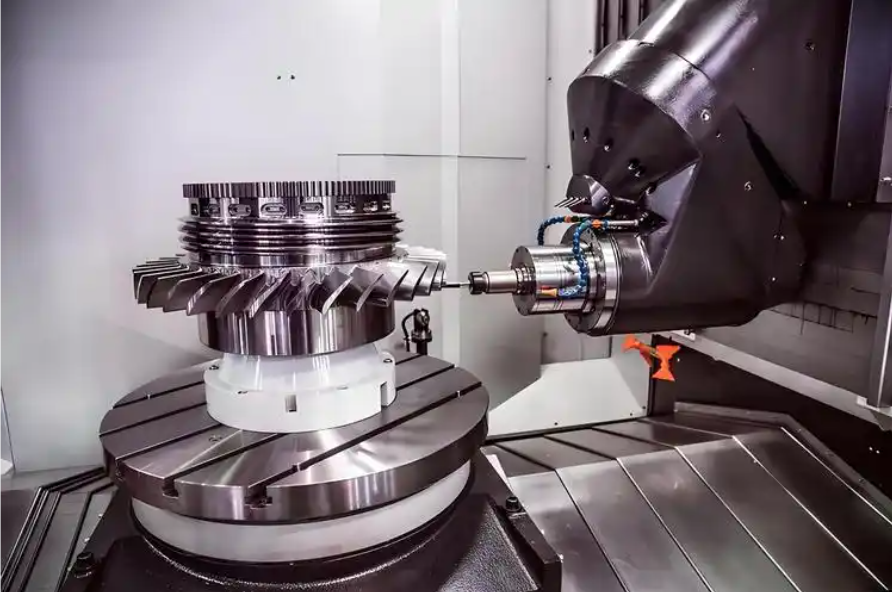

Five-axis machining center is a high-tech and high-precision processing center specifically designed for processing complex curved surfaces. This machining center system has a significant influence on various industries such as aviation, aerospace, military, scientific research, precision machinery, and high-precision medical equipment in a country. The five-axis numerical control machining center system is the only means to solve the processing of components such as impellers, blades, marine propellers, heavy generator rotors, steam turbine rotors and large diesel engine crankshafts.

Product Features:

The five-axis machining center boasts high efficiency and high precision. It enables complex processing to be completed with just one setup of the workpiece. It can handle the processing of modern molds such as automotive parts and aircraft structural components. There is a significant difference between a five-axis machining center and a five-sided machining center. Many people are unaware of this and mistakenly identify a five-sided machining center as a five-axis machining center. The five-axis machining center has five axes: x, y, z, a, and c. The x y z and a c axes form five-axis coordinated processing, and it excels in spatial surface processing, special-shaped processing, hollowing out processing, drilling, inclined holes, inclined cutting, etc. On the other hand, a “five-sided machining center” is similar to a three-axis machining center, except that it can perform processing on five surfaces simultaneously, but it cannot perform special-shaped processing, inclined hole drilling, or cutting inclined surfaces, etc.

Technical advantages

* High efficiency:

Completes multi-face processing in one setup, reducing process switching time.

* High precision:

The positioning accuracy can reach 0.02mm/m, and the repeat positioning accuracy is 0.01mm/m. Suitable for high-demanding fields such as the processing of aircraft engine blades.

* Cutting optimization:

By adjusting the tool axis direction to maintain the optimal cutting state.

It improves the surface finish.

Mechanical Structure and Classification

The mechanical design of five-axis machines is diverse, and mainly includes the following types:

1. Double pendulum head type:

Two rotating axes are integrated into the main head, suitable for processing large workpieces.

2. Double turntable type:

The workpiece moves along with the turntable, suitable for processing small precision parts.

3. One pendulum and one rotation type:

A combined structure that balances flexibility and load-bearing capacity.

The five-axis machining center is a high-tech means that turns the impossible into the possible. It can handle all kinds of spatial curved surfaces and special-shaped processing. Not only can it complete the mechanical processing tasks of complex workpieces, but it can also significantly improve the processing efficiency and shorten the processing process.