In engineering design and manufacturing, Q235 steel is a commonly used carbon structural steel with extensive applications and significant importance. This article will explore the characteristics, applications, and importance of Q235 steel, as well as its performance and role in various fields.

- Characteristics of Q235 Steel

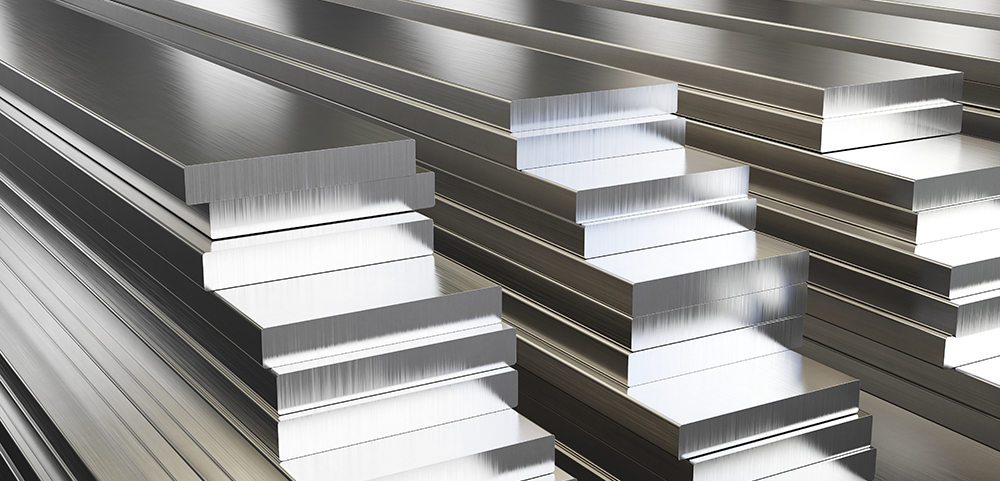

Q235 steel is a low-carbon steel, primarily composed of iron (Fe) and carbon (C). This composition endows Q235 steel with good plasticity and toughness, making it suitable for withstanding impact and vibration. Additionally, Q235 steel is relatively inexpensive, facilitating large-scale production and application. Moreover, Q235 steel exhibits excellent processing properties, with good weldability and machinability, allowing for effective processing and shaping. With appropriate heat treatment, the hardness and strength of Q235 steel can be enhanced. These characteristics give Q235 steel broad application prospects in the manufacturing process.

- Applications of Q235 Steel

The diverse applications of Q235 steel across different fields highlight its versatility. In the construction industry, Q235 steel is used to manufacture reinforcing bars, section steel, and steel plates, enhancing the strength and stability of building structures. In bridge construction, Q235 steel is employed to produce bridge components such as main beams and bridge decks, reducing the weight of the bridge and increasing its load-bearing capacity. In shipbuilding, Q235 steel is used to construct hull components like the ship’s shell and deck, improving the vessel’s resistance to wind and waves and ensuring stable navigation. In the automotive industry, Q235 steel is utilized to manufacture frames and wheels, enhancing the vehicle’s load-bearing capacity and driving stability. In mechanical manufacturing, Q235 steel is used to produce gears, bushings, pistons, and other mechanical parts, improving the stability and durability of mechanical equipment.

- Importance of Q235 Steel

The importance and widespread use of Q235 steel are not only reflected in its performance characteristics but also in its contribution to economic development and social progress. Firstly, the low production cost of Q235 steel makes it suitable for large-scale production, meeting the needs of engineering construction. Secondly, the good plasticity and toughness of Q235 steel enable it to adapt to various complex environments and load conditions, ensuring high reliability and safety. Finally, the broad application range of Q235 steel meets the demands of different fields, playing a significant role in promoting economic development and social progress.

- Limitations and Optimization of Q235 Steel

Despite its extensive applications and significant importance, Q235 steel has some limitations in practical use. For example, its corrosion resistance is relatively poor, making it susceptible to humid environments, thus requiring appropriate anti-corrosion measures in certain special conditions. Additionally, the strength and hardness of Q235 steel are relatively low, making it unsuitable for high-strength and high-hardness applications. To overcome these limitations, Q235 steel can be modified through processes such as alloying and heat treatment to improve its overall performance. For instance, adding alloying elements can enhance the corrosion resistance and hardness of Q235 steel, while heat treatment can refine its microstructure and properties, increasing its strength and toughness. These optimization measures enable Q235 steel to better meet the needs of various engineering applications.