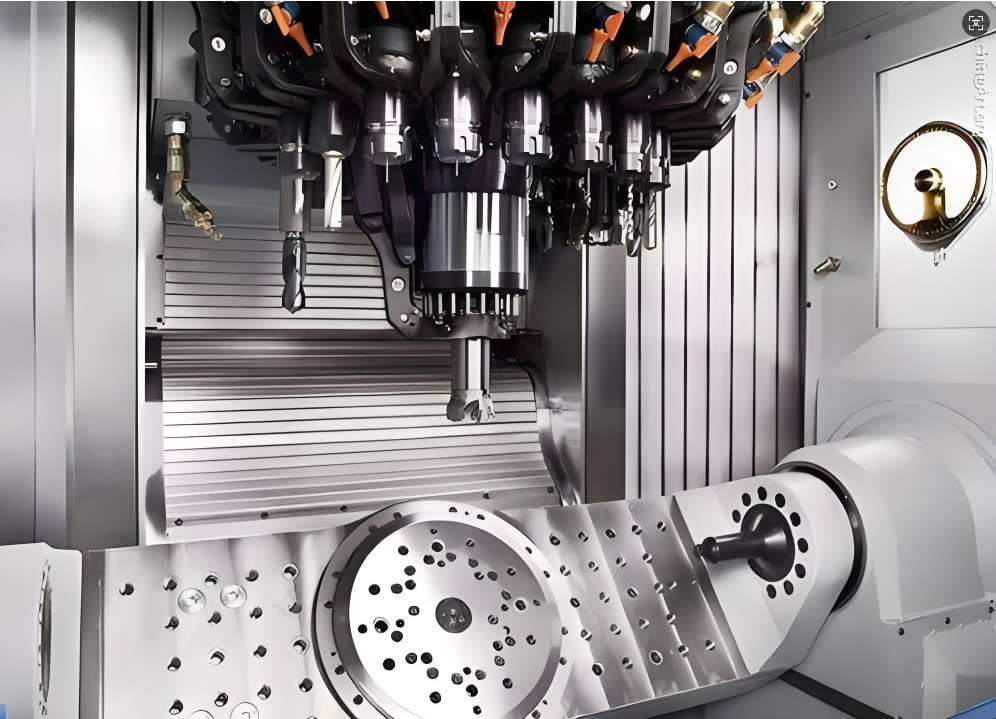

Machining Center is developed from CNC milling machine. The obvious difference between the machining center and the CNC milling machine is machining center has the ability of automatic tool changing. By installing different types tools on the tool magazine, the machining center can change the tool on the spindle through the automatic tool changing devise during one clamping process, thus achieving multiple process functions.

Machining Center is combine from machinery equipment and CNC system, which is a kind of high efficiency automatic machine, that is suitable to machine the complex spare parts. Machining Center is one of the most widely produced and applied CNC machine tools in the world. Its comprehensive processing capacity is relatively strong. After the workpiece is clamped once, it can complete a considerable amount of processing contents. The processing accuracy is relatively high. For medium difficulty batch workpieces, its efficiency is 5 to 10 times that of ordinary equipment. Especially, it can complete many processing tasks that ordinary equipment cannot accomplish. It is more applicable for single-piece processing with complex shapes and high precision requirements, as well as for small and medium batch multi-variety production.It integrates milling, boring, drilling, tapping and thread-cutting functions onto one machine tool, thus enabling it to possess multiple processing procedures and processing techniques. Machining centers are classified according to the spatial position during spindle processing as follows: horizontal and vertical machining centers. According to their processing purposes, there are: boring and milling machining centers, and compound machining centers. According to their special functions, there are: single-spindle, double-spindle and multi-spindle machining centers. There are also machining centers with single axis, double axis, three axes and interchangeable spindle boxes. According to the guide rails, there are: linear rail machining centers, hard rail machining centers, etc.