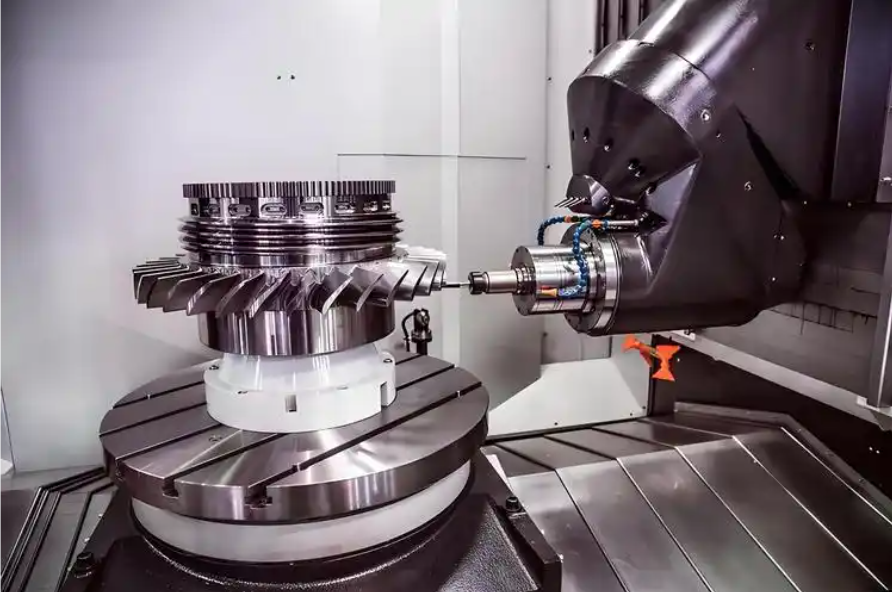

Exploring the future of machining: technological innovations, applications and trends

Machining, a field that has accompanied mankind’s progress since the Industrial Revolution, is undergoing an unprecedented transformation. As technology continues to advance, the future of