1. Machine and Tooling Factors

This category relates to the physical equipment used to create the product.

- Machine Capability & Condition:

Stiffness and Rigidity: Lack of rigidity leads to vibrations (chatter) and deflection under cutting forces, causing dimensional errors.

Geometric Accuracy: Wear on guideways, lead screws, and spindles degrades the machine’s inherent precision.

Backlash: Clearance between mechanical components (like gears and screws) causes lost motion and positioning errors.

Thermal Stability: Machines generate heat from motors, friction, and cutting processes. Uneven expansion and contraction (thermal growth) can significantly alter the machine’s geometry and accuracy.

- Tooling:

Tool Wear: Cutting tools, inserts, and drills wear down over time, changing the geometry of the cut and increasing forces, which leads to size and surface finish inaccuracies.

Tool Deflection: Long, slender tools can bend under pressure, especially in milling and drilling, creating features that are not to size or location.

Tool Quality & Presetting: Variations in tool geometry from one tool to the next, or incorrect setup in the tool holder, introduce immediate errors.

2. Material Factors

The raw material itself is a major source of variation.

- Material Properties:

Inconsistency: Variations in hardness, grain structure, and chemical composition between batches can cause the material to behave differently during processing.

Dimensional Stability: Some materials (e.g., plastics, certain metals) can warp, shrink, or expand after processing due to internal stress relief or moisture absorption.

Work Hardening: The material can become harder during processing, affecting subsequent operations and tool wear.

- Input Quality:If the incoming raw material or semi-finished component is out of spec, it is nearly impossible to produce an accurate final product.

3. Human Factors

The role of the people operating and managing the process.

Skill and Training: An operator’s understanding of the process, machine, and quality standards is critical. Inconsistent techniques lead to inconsistent results.

Procedural Adherence: Failure to follow Standard Operating Procedures (SOPs) introduces unwanted variation.

Fatigue and Concentration: Manual operations are susceptible to errors when an operator is tired or distracted.

Interpretation: Subjective judgments in measurement or setup can vary from person to person.

- Method and Process Factors

How the product is made.

- Process Parameters:The settings of the process itself—cutting speed, feed rate, temperature, pressure, cycle time—have a direct and profound impact on accuracy. Incorrect parameters can cause tool deflection, heat buildup, and poor surface finish.

- Setup and Fixturing:

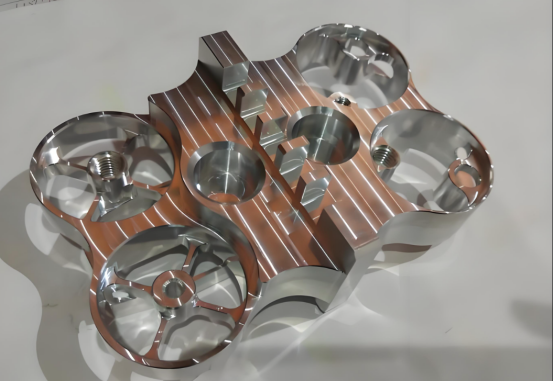

Workholding: Inadequate or worn-out fixtures, clamps, and vices can allow the part to move during processing, leading to location and geometry errors.

Setup Errors: Incorrectly zeroing the machine, using the wrong datums, or misaligning the part in the fixture are common sources of major inaccuracies.

- Process Sequence:The order of operations is critical. For example, performing a heat treatment step at the wrong time can cause distortion that makes previous machining operations inaccurate.

5. Measurement and Inspection Factors

You cannot improve what you cannot measure correctly. The measurement system itself can be a source of perceived inaccuracy.

- Gauge Accuracy and Calibration:Using uncalibrated or inherently inaccurate measuring instruments will provide false data.

Gauge Repeatability & Reproducibility (GR&R):

Repeatability: Can the same person get the same result multiple times with the same gauge?

Reproducibility: Can different people get the same result with the same gauge?

A poor GR&R means the measurement variation is a significant portion of your tolerance, making it impossible to judge the true product accuracy.

- Measurement Technique:Incorrect use of measurement tools (e.g., wrong pressure with a caliper, misreading a micrometer) leads to errors.

- Environmental Effects on Measurement:Temperature in the quality lab can affect both the part and the measuring instrument (e.g., CMMs).

6. Environmental Factors

The conditions in the factory.

Temperature: The most critical environmental factor. Most materials expand with heat. A shop floor that fluctuates in temperature will cause parts and machines to change size throughout the day.

Humidity: Can affect certain materials (e.g., wood, plastics, composites) and can lead to corrosion on precision surfaces.

Vibration: External vibrations from nearby machinery, forklifts, or even building HVAC systems can disrupt delicate machining processes and precision measurements.

Cleanliness: Dust, chips, and debris on locating surfaces, fixtures, or measurement platforms can cause misalignment and inaccurate readings.

7. Design Factors

Sometimes the root cause originates in the product design.

Design for Manufacturability (DFM): A design that is difficult or impossible to manufacture consistently will always struggle with accuracy. Examples include sharp internal corners, features that are inaccessible to standard tools, or unrealistic tolerances.

Tolerance Stack-Up: The cumulative effect of tolerances from individual components in an assembly. Poorly managed stack-ups can result in an assembly that does not function, even if each individual part is within its specified tolerance.